If you ever questioned why shipment tracking isn’t always precise and reliable, you are asking for Real-Time Logistics Visibility. Customers expect live updates, operations teams want to minimize surprises, and finance aims for predictable costs. Achieving this level of clarity is absolutely possible. With today’s shipment tracking, sensor technology, GPS tracking, and smarter platforms, real-time visibility is finally practical, not just for global giants, but for growing shippers and 3PLs too.

Below, we’ll break down what real-time visibility actually means, how it works, where IoT in logistics fits in, how predictive ETA helps you make better promises, and how to roll it out without blowing up your budget or your processes.

Think of visibility as a single, continuous shipment timeline and transport monitoring event, transport modes, including multiple carriers, and partners, constantly refreshed through connected devices and real-time data streams. Real-time visibility typically covers:

With all that in one place, you get supply chain transparency that’s actually usable, not a stack of spreadsheets that’s out of date by the time you hit refresh.

Legacy tracking depends on inconsistent barcode scans, which is better than nothing; however, it creates large visibility gaps during transfers. Real-time systems, on the other hand, continuously stream data. Small, low-cost devices and vehicle-tracking data for your visibility platform in real time. So you can monitor events as they occur, not only after the fact.

Last-mile delivery can make or break your logistics costs, nearly 41% of the total. This is often where delays, missed schedules, and inquiries like “Where’s my order?” arise. By utilizing real-time visibility, teams can reduce costs by preventing waste, avoiding failed deliveries, rerouting deliveries as necessary, and organizing transfers.

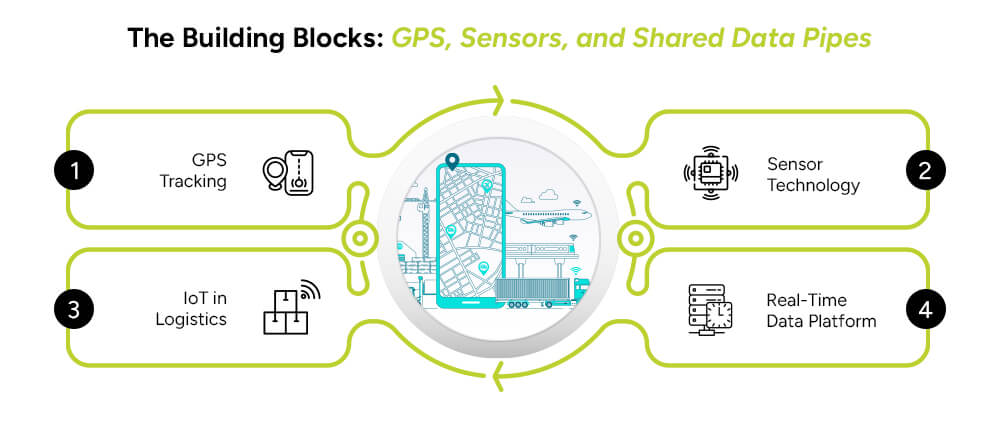

Everything in modern visibility stacks starts with just a few key building blocks:

The explosion of connected devices is what makes real-time affordable and scalable. Research indicates the number of connected IoT devices reached 16.6 billion in 2023 and is expected to grow to 41.1 billion in 2030, a wave that’s directly powering logistics visibility use cases (from trailer tracking to pallet-level monitoring).

Traditional ETAs assume everything will go smoothly, while predictive ETAs use real-time data: traffic, weather, shipping delay, dwell history, driver hours, and lane performance. This dynamic approach helps planners, warehouses, and customers adjust proactively to avoid delays.

With real-time visibility, operational efficiency improves because you’re not longer operating in the dark. Common, measurable wins include:

Even small improvements multiply across lanes, timelines, and teams, turning the last mile into a real source of savings.

Great visibility isn’t a dashboard you admire; it’s a shared view people act on. Best practices:

Freight monitoring extends beyond dots on a map to the physical state of goods. For temperature-controlled shipments, add:

This is visibility that prevents loss, not just reports it after the fact.

Customers don’t judge you by upstream brilliance; they judge you by the doorbell ring. Strong last-mile tracking combines:

Because the last mile drives the largest cost share, it’s also where visibility delivers the fastest ROI.

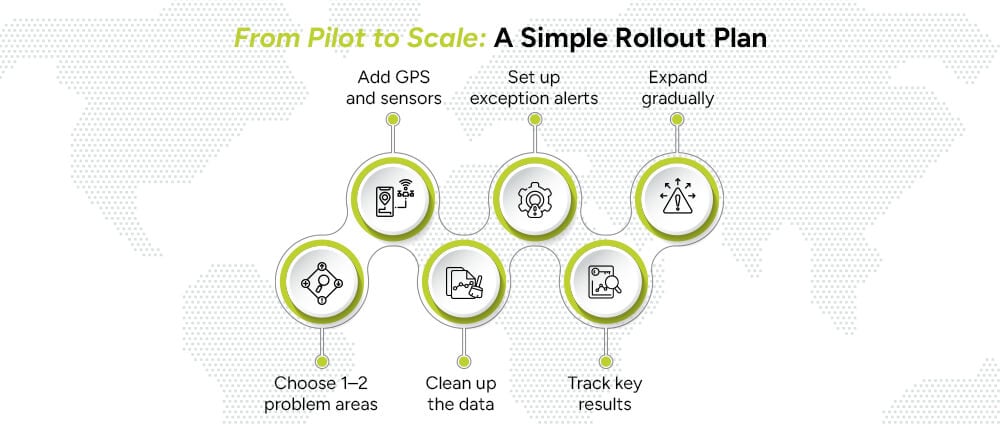

You don’t have to do everything at once. Start small and grow step by step. This is how you can go about developing your logistics app:

Focus on lanes or customers where delays, claims, or “where’s my order?” calls occur most often. Decide how you’ll measure success (like improving on-time delivery or cutting detention fees).

Use vehicle trackers and portable devices to track shipments in real time. For sensitive goods, add sensors that check temperature or handling.

Make sure information from carriers and devices follows the same format. Clean, consistent data makes the system reliable.

Don’t just look at dashboards—set rules so issues go straight to the right person to fix. For example, someone should respond to a delay within minutes, not hours.

Keep an eye on numbers like on-time delivery, ETA accuracy, claims, and customer calls. Share results with carriers and celebrate improvements.

Once it’s working well, roll it out to more lanes, partners, and transport modes. You can even use pallet-level trackers for high-value or fragile goods.

Real-time visibility isn’t a shiny gadget; it’s a control system for your network. It turns uncertainty into manageable exceptions, transforms customer experience, and cuts the hidden costs of firefighting. As the IoT device wave grows and predictive analytics improve, the gap between scan-based tracking and real-time operations will only widen. Teams that move now will set a higher bar for reliability and keep it.

This is where Arpatech can help: by integrating advanced tracking tools, IoT-enabled devices, and predictive analytics into your logistics processes, we make it easier for you to gain true supply chain transparency, boost efficiency, and deliver the kind of customer experience that sets you apart.

Have a free consultation with our developers to rethink, reimagine, and revamp your logistics application development today.

It’s the continuous, live picture of your shipments: location (via GPS tracking), condition (via sensor technology like temperature, shock, tilt, humidity, and light), milestones (pickup, in-transit, out for delivery, delivered), exceptions (delays, route deviations, dwell, excursions), and a predictive ETA that updates as conditions change. Done right, it’s shared across your TMS, WMS, customer portals, and partner networks so everyone acts from the same real-time data.

By shrinking the “unknowns” that cause waste. You’ll lower detention/dwell with earlier notices and better dock scheduling; reduce spoilage and damage with live condition alerts; avoid failed first deliveries with last-mile tracking and proactive customer updates; and trim manual effort by replacing status-chasing with exception queues. These improvements stack up, especially in the last mile, where a large share of logistics costs sits.

Pick a small set of KPIs and track them weekly:

If those curves move the right way as your visibility coverage expands, you’re on the right track.